Stainless Steel Reactor For Chemical Industry

Basic Info

Model No.: DFG50-DFG3000

Product Description

Products Description

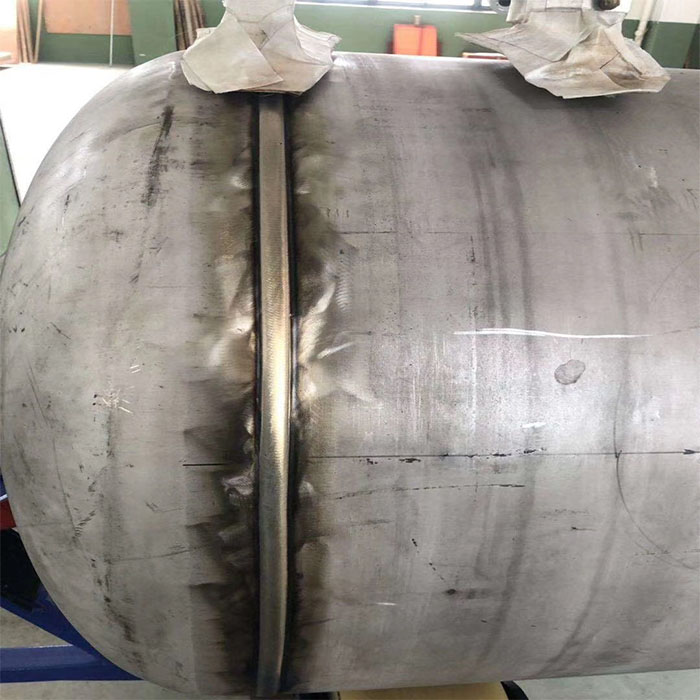

Reaction Kettle is a traditional production equipment inpharmaceutical, chemical, food, light and other industries. It plays an important role in the process of liquid liquid mixing, liquid powder mixing and so on. According to the needs of customers, the preparation of a variety of mixing paddle, in order to achieve different reaction results. The capacity, the size of the reactor and the feeding way can be designed according to the site environment, with the production process. Is the traditional Chemical Industry must produce equipment. Our company produces reactor is composed of upper and lower head, inner cylinder, jacket seal, stirring transmission device and supporting etc, according to the production process and operating conditions, the jacket heating type divided into electric bar heating, steam heating, heating oil, seal device for packing seal and Mechanical Seal, mixing type anchor, slurry type, turbine type, push type and frame type etc.. The number of holes, specifications, other requirements can be designed and manufactured according to user requirements, the material is SS304, SS316L, Titanium, Hastelloy, PTFE lined and other materials.

➤The reaction kettle is composed of kettle body, kettle cover, agitator, heating jacket, supporting and driving devices, seal devices, and etc. and equipped with electric heating rods.

➤Considering clients’ different producing technology and operating conditions, usually mixing patterns are divided into anchor,propeller, turbo, push or frame. The support seat has two kinds, hanging or back supporting type. There are holes for oil in and out, venting, and temperature monitoring in the jacket. At the bottom of the kettle, there is a discharge hole.Cycloidal pinwheel reducer, variable-speed reducer and others could be applied in the rotating mechanism. The sealing device can use machines; Sleeve, semi-tube and coil pipe structure can be used in heating and cooling. There are several heating mode,such as steam, electric heating, heat conduction oil, etc. In order to meet different requirements of acid-and alkali-proof,high temperature resistance, wear resistance, corrosion resistance and others under diffrent working environments, reaction kettles can be designed and manufactured based on clients’ requests.

Operating Requirements

➤The vent pipe installed in the upper part of the jacket should be unblocked.

➤Oil should be slowly heated, especially in the first warming period, you should pay attention to preventing oil and steam from blasting boiling.

➤If there are no materials (heat absorbing medium) in the kettle, don’t heat jacket for testing.

➤The heating speed and insulation status(on/off) can be adjusted by valves or temperature controller

| Specification (L) | Inner tank diameter (mm) | Jacket diameter (mm) | Motor Power (kw) | Rotational Speed (r.p.m) |

| 30 | 400 | 500 | 0.6-1.1 | 60-80 |

| 50 | 500 | 600 | 0.6-1.1 | 60-80 |

| ... | ... | ... | ... | ... |

| 32000 | 3000 | 3200 | 37 | 50-100 |

| Type | Nominal Capacity (L) | Actual Capacity (L) | Tlectro-thermal power | Oil Jacket VOlume (L) | The Size of the pot(mm) | Jacket Size (mm) | External Size (mm) | Power (n/k) | Mixing Soeed (r.p.m) |

| DFG50 | 50 | 78 | 4*2KW | 96 | 400 | 600 | 824*2015 | 1450/1.1 | 80 |

| DFG100 | 100 | 127 | 6*2KW | 127 | 500 | 700 | 1004*2120 | 1450/1.1 | 80 |

| ... | ... | ... | ... | ... | ... | ... | ... | ... | ... |

| DFG3000 | 3000 | 3056 | 18*5KW | 800 | 1600 | 1800 | 2250*4250 | 1450/4 | 80 |

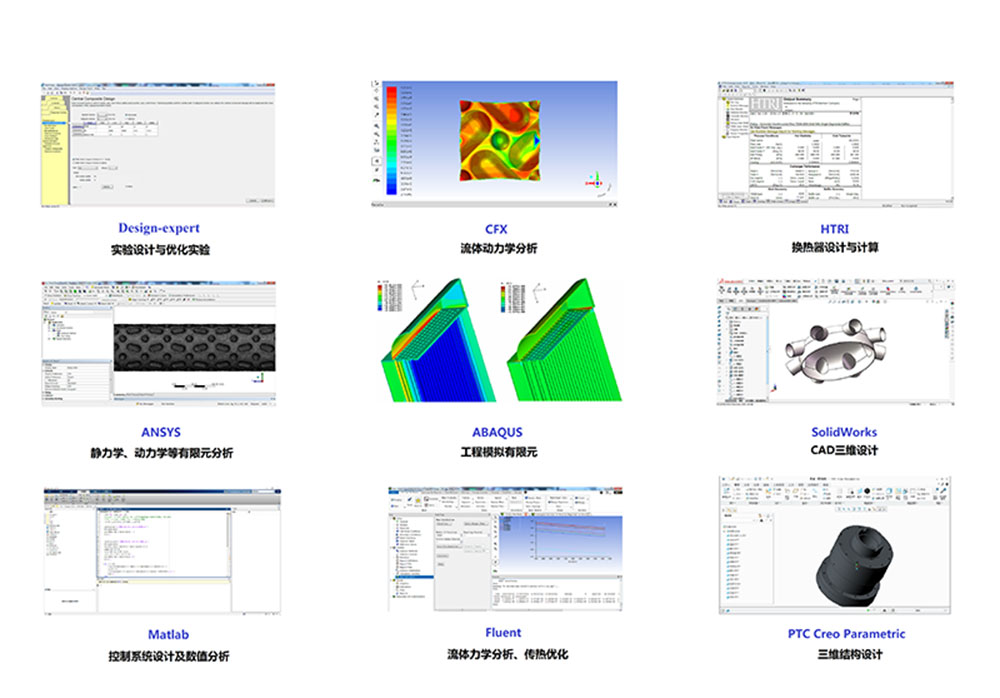

Design / Calculation Software

1. Multifunctional “Three in One” (filtering, washing and drying)

3. Sterile double-cone dryer

4. Rake Vacuum Dryer /Paddle Vacuum Dryer

5. Plate-fin Heat Exchanger

➤Our advantage

1. Special Equipment: Pressure Equipment, Equipment made of anti-corrosion materials, Sterile Equipment

Equipment made of anti-corrosion materials includes: anti-corrosion lining plastic/ PTFE/ enamel,

2.Customized Design: Double-Cone in 20L-20m³

Rake Dryer (with mechanical seal) in 16 m³

DN300-DN600 “Three in One”

3.Design/Calculation Software

➤Scope of business

1. On-site Inspection

Product Categories : Stainless Steel Reactor > Reaction Kettle